TRANSPARENCY

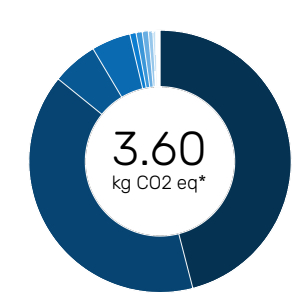

impact per sweater

We conduct a comprehensive life cycle analysis for every product we create, using real data on CO2 emissions, water, and chemical usage from our own closed-loop production process.

Our circular, locally-made sweater saves 2.54 kg of CO2 and 2,000 liters of water—highlighting the significant difference between a recycled sweater produced in Europe or Turkey and a completely new one made in Asia.

OUR PROCESS

fine sorting - fiber - spin - fabric