OUR PROCESS

Making fashion from fashion

THE PROCESS

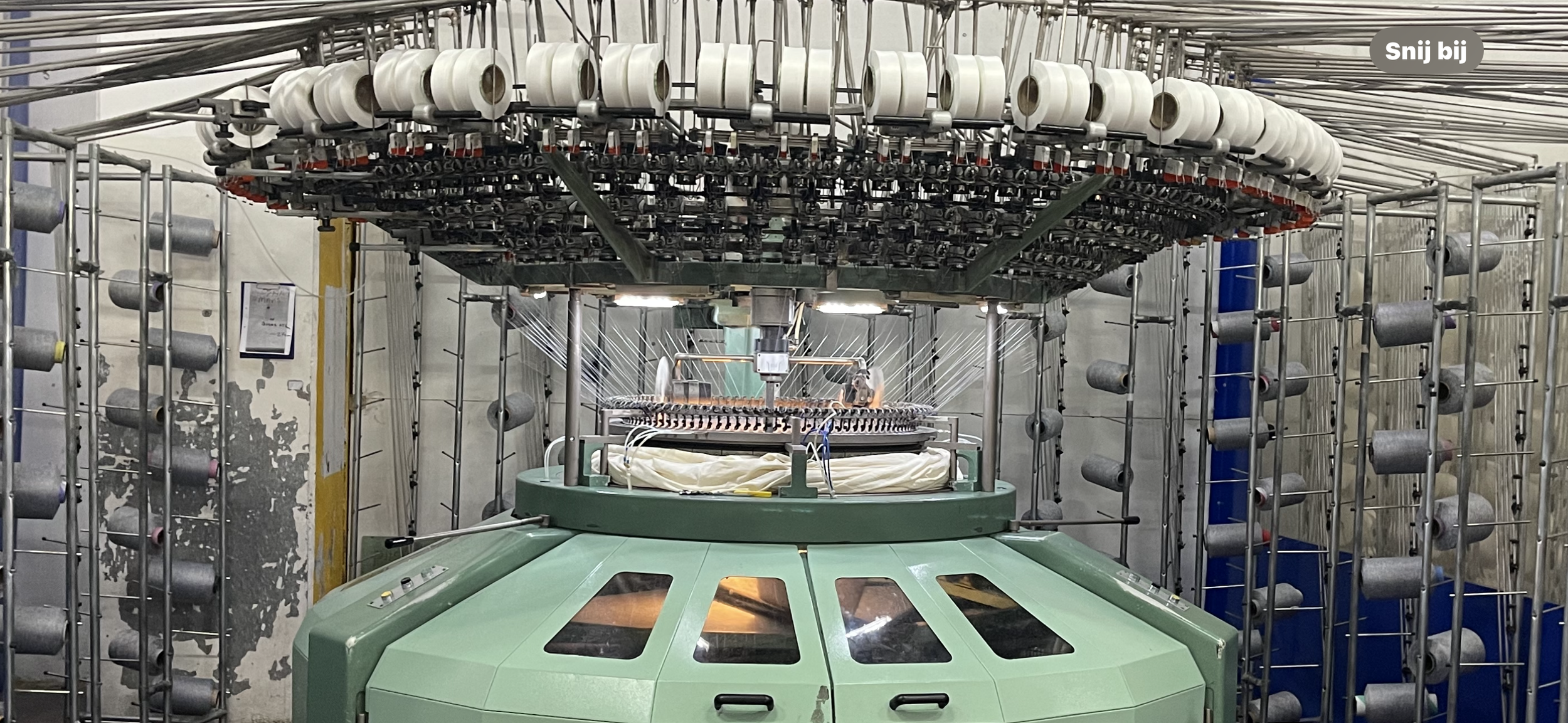

We turn complexity into clarity with a hands-on approach that proves circular, waste-free fashion is possible. In the Amsterdam Metropolitan Region, we operate the world’s first fully automated fiber-to-fiber production line, transforming regional textile waste into premium raw materials. This breakthrough marks the first scalable solution for converting non-rewearable clothing into high-quality fibers, setting a new global benchmark for the circular fashion industry. Through this closed-loop system, and in collaboration with our spinning and knitting partners, we provide truly circular fabrics and finished products — from t-shirts and polos to sweaters — for fashion and workwear brands.

TRANSPARENCY

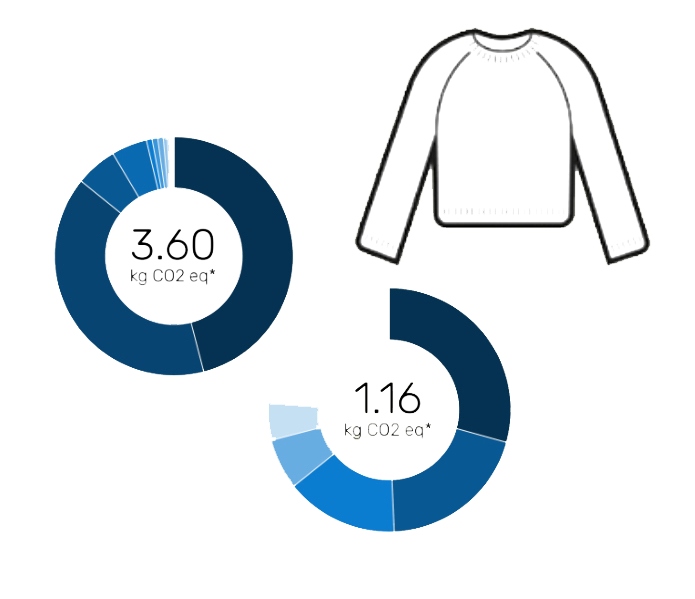

impact per sweater

We conduct a comprehensive life cycle analysis for every product we create, using real data on CO2 emissions, water, and chemical usage from our own closed-loop production process.

Our circular, locally-made sweater saves 2.54 kg of CO2 and 2,000 liters of water—highlighting the significant difference between a recycled sweater produced in Europe or Turkey and a completely new one made in Asia.