OUR PROCESS

Making fashion from fashion

TRANSPARENCY

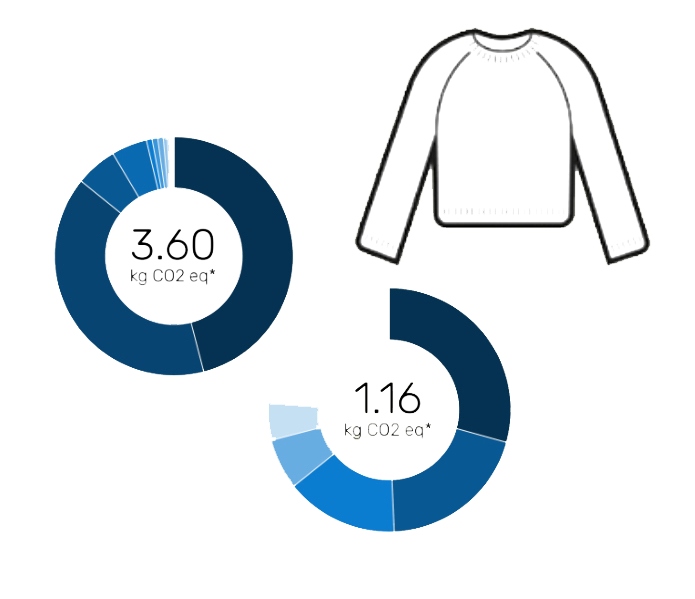

impact per sweater

We conduct a comprehensive life cycle analysis for every product we create, using real data on CO2 emissions, water, and chemical usage from our own closed-loop production process.

Our circular, locally-made sweater saves 2.54 kg of CO2 and 2,000 liters of water—highlighting the significant difference between a recycled sweater produced in Europe or Turkey and a completely new one made in Asia.

THE PROCESS

We turn complexity into clarity with a hands-on approach that proves circular, waste-free fashion is possible. In the Amsterdam Metropolitan Region, we operate the world’s first fully automated fiber-to-fiber production line, transforming regional textile waste into premium raw materials. This breakthrough marks the first scalable solution for converting non-rewearable clothing into high-quality fibers, setting a new global benchmark for the circular fashion industry. Through this closed-loop system, and in collaboration with our spinning and knitting partners, we provide truly circular fabrics and finished products — from t-shirts and polos to sweaters — for fashion and workwear brands.

Local fine sorting & cleaning

In our sorting facility we are capable of processing up to 2 millions of kilos of local waste streams. We developed the world’s first NIR technology-based sorter, capable of classifying textiles by color and material, and an advanced system that removes buttons, zippers, and labels using metal detection and camera technology.

Smart fibering

At the heart of this system is the world’s first fully automated fiberizing machine, engineered specifically to process discarded clothing. Designed for flexibility, the machine line can handle a wide variety of materials in different ways, making it uniquely capable of tackling the complexity of textile waste streams. Through the reuse of colors embedded in discarded clothing, the system reduces reliance on water- and chemical-intensive dyeing, cutting the environmental impact even further. By integrating this breakthrough technology into Brightfiber Textiles’ recycling ecosystem, we enable scalable, high-quality fiber-to-fiber recycling — setting a new global benchmark for the circular fashion industry.

Sustainable blending

Brightfiber Textiles sets its own standard when it comes to circular and sustainable textile products. Each product contains a minimum of 40% recycled clothing sourced from local waste streams, blended exclusively with other sustainable materials.

European spinning partners

Over the past few years, Brightfiber Textiles has developed its own premium collection of yarns collaboration with experienced spinning partners across Europe. Each product contains a minimum of 40% recycled clothing sourced from local waste streams, blended exclusively with other sustainable materials.

European knitting partners

Produced in Europe and Turkey, the entire process operates within a fully closed-loop system. Our knitting partners play a vital role in closing the loop. By working with specialized mills that share our vision for circularity, we transform Brightfiber’s recycled yarns into high-quality fabrics with minimal waste. These collaborations ensure precision, consistency, and scalability — from jersey and pique to structured knits — enabling us to deliver sustainable textiles tailored to the needs of fashion and workwear brands. Together, we demonstrate that circular production is not only possible, but commercially viable at scale.

End product

Under the brand name BRIGHT.FIBER INSIDE®, the company supplies truly circular and sustainable fabrics and end products—such as t-shirts, polos, and sweaters— to fashion and workwear brands. Every product includes a detailed life cycle analysis (LCA), allowing consumers to see exactly how much CO2 and water they’ve saved compared to conventional cotton or wool garments.